Today’s telecom networks face the challenge of installing an increasing amount of active equipment outside existing telecom buildings, closer to end-users. This shift is driven by the growing demand for both mobile and fixed traffic, coupled with the need to upgrade to higher frequencies/bandwidth, requiring shorter distances between end-users and network equipment. This results into an increasingly dense network structure and systems that need to be installed in the field and requires active powering almost anywhere. But the mains power network of the utility provider is not available everywhere or requires heavy investments to build up up such structures.

Beside the costs of such power provision, which can amount up to several 10.000 € – with a huge impact to the TCO costs – also the very long deployment times of up to 6-12 months will limit the fast rollout of the new ultra-high bandwidth and dense networks.

Energise mobile 5G networks

From 500 W to 3,000 W Remote Powering scenarios

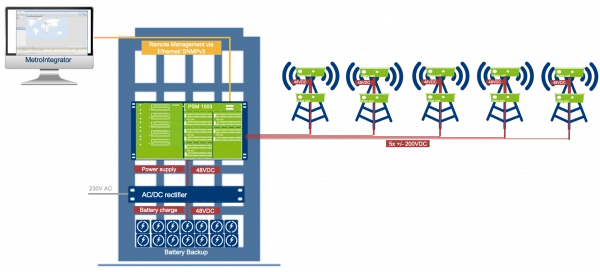

Here the RPS 3000 system comes into place as it is designed to remotely power active equipment in the telecommunication and mobile network environment, such as active antenna systems (i.e. RRH) and micro, as well as nano cell equipment with a power range from 500W of up to of 3.3 kW from a central power injection point. This point could be either a telecommunication exchange or IT building with an existing 48 V DC battery backed-up power grid or a 230 V AC direct power injection when operating directly in the field (i.e. in a street cabinet) at a location where mains power is easily available and where already active telecom or mobile equipment is in place and where potentially the data connection is also effected towards the remote systems.

By using the RPS 3000 system and installing the central components at such locations where power is available, and by usage of standard power or even hybrid cables, the TCO can be reduced by up to 40%, because only single digging (or cabling) is needed for the data and power cabling to the remote sites.

Also, the number of power meters and local battery backups is decreased heavily, which is a big advantage for network operators. In addition to this, the number of conversion cycles from 230 V AC mains power to the typically 48 V DC power input of telco equipment can be reduced, which increases the overall efficiency.

SINGLE hybrid cable for data & power

- Ener5G works on a SINGLE hybrid cable to carry both power and data to radio heads

- A combination of fiber and copper within a single cable is available from many vendors (i.e. Prysmian)

High power delivered over high distances

- The central site can deliver to remote sites up to 3 kW over HIGH DISTANCES of up to 1,000 meters and 1 kW of up to 2,500 meters

Efficient high voltage transmission

- Ener5G Remote powering is using high voltage up-conversion at +/-190 V DC, a perfect way to transfer energy with MINIMAL POWER LOSSES, for use in P2P, P2MP or centralized RAN architecture with baseband units (BBUs)

Maximum safety and Protection

- Ener5G is safe-touch and eliminating danger to life

- If there is improper wiring, in case of a short circuit, or if a person touches the transmission lines, the transmitter will cut out within a few milliseconds

Suitable for DUCT standard

- Some combination of fibre and copper within a single cable can be blown into a STANDARD DUCT

- Only one single DIGGING is required as civil works to transmit both power and data to each location

Centralized batteries – cost reduction

- Centralized batteries at the BBU site will decrease CAPEX and OPEX costs

- There is NO NEED to equip each small cell with a battery backup

Energy Backup to a Solar system

- A solar-only system requires battery storage system, to use solar energy even overnight

- Ener5G could inject energy in a smart way as backup to a solar system without a battery

Enabling “Energy as a service”

- The MetroIntegrator Management System can measure power consumption on each remote site

- The Ener5G system can enable Energy provision services to end customers

Use Case

Remote powering of 5 nano cells – each 500 W

One of the most common applications for the RPS 3000 remote powering system is feeding micro and nano cell mobile equipment for the forthcoming densification of 5G mobile networks. Here in this case up to 5 nano cells can be powered by the RPS 3000 remote powering system within a radius of up to several kilometers around the central power injection point. When using another power up-converter in the RPS 3000 rack, also high redundancy can be provided for the unlikely case that one of the maximum 6 up-converters in the central power rack would fail.

Via 5 dedicated copper cables or a 10-wire cable the power transfer to the 5 different locations will be realized. The safe startup procedure and the comprehensive line control safety features of the RPS 3000 secure the power transfer over the outgoing lines in the field and protect humans and machines that might come in contact with the power line. So, in critical situations, such like ashort circuit of one of the copper lines as an example, this dedicated line and respectively equipment will be turned off immediately. Furthermore, this setup and system behaviour allows the usage of multiple copper wires with a lower cross section – like those used in hybrid cables to transfer the needed power amount over several lines on longer distances while securing each of the copper lines.

On the remote side, the high remote voltage will be converted back into the standard and unified 48V DC needed for the telecom equipment.

Energise mobile 5G Networks now!

Please fill out all required fields* of the contact form. We will contact you as soon as possible.